Introduction: Why Compromise is Not an Option for Your Eyes

If you wear regular corrective glasses and work or play in a hazardous environment, you face a critical question: how do you get clear vision and certified eye protection at the same time? Simply wearing bulky safety goggles over your everyday glasses is often uncomfortable, compromises the seal of your protection, and can distort your vision.

The answer is prescription safety glasses. This guide is designed for professionals, hobbyists, and safety managers who need to know the official standards (like ANSI Z87.1), the best materials (such as Polycarbonate and Trivex), and the exact steps to choose the perfect, custom-fit eyewear for maximum comfort and safety in any situation. Your vision is too valuable to risk.

The Core Problem: Why Regular Glasses Aren’t Safe Glasses

It’s a common and dangerous misconception that normal prescription glasses offer enough protection. They do not. Everyday lenses and frames are not engineered to withstand high-velocity impact, flying debris, or chemical splashes.

Key Differences Between Standard and Safety Eyewear

- Impact Resistance: Standard lenses can shatter upon impact, turning into secondary projectiles that cause severe eye injury. Prescription safety glasses are designed to absorb and deflect force without breaking, often featuring robust side shields for peripheral protection.

- Material: Regular lenses are often made from CR-39 plastic or glass, materials that lack the necessary durability. Safety lenses are made from materials like Polycarbonate or Trivex, which are dramatically more resistant to impact.

- Certification: Only safety eyewear is tested and marked by recognized safety bodies to meet strict regulations. If your eyewear doesn’t have a certification mark, it is not approved safety gear.

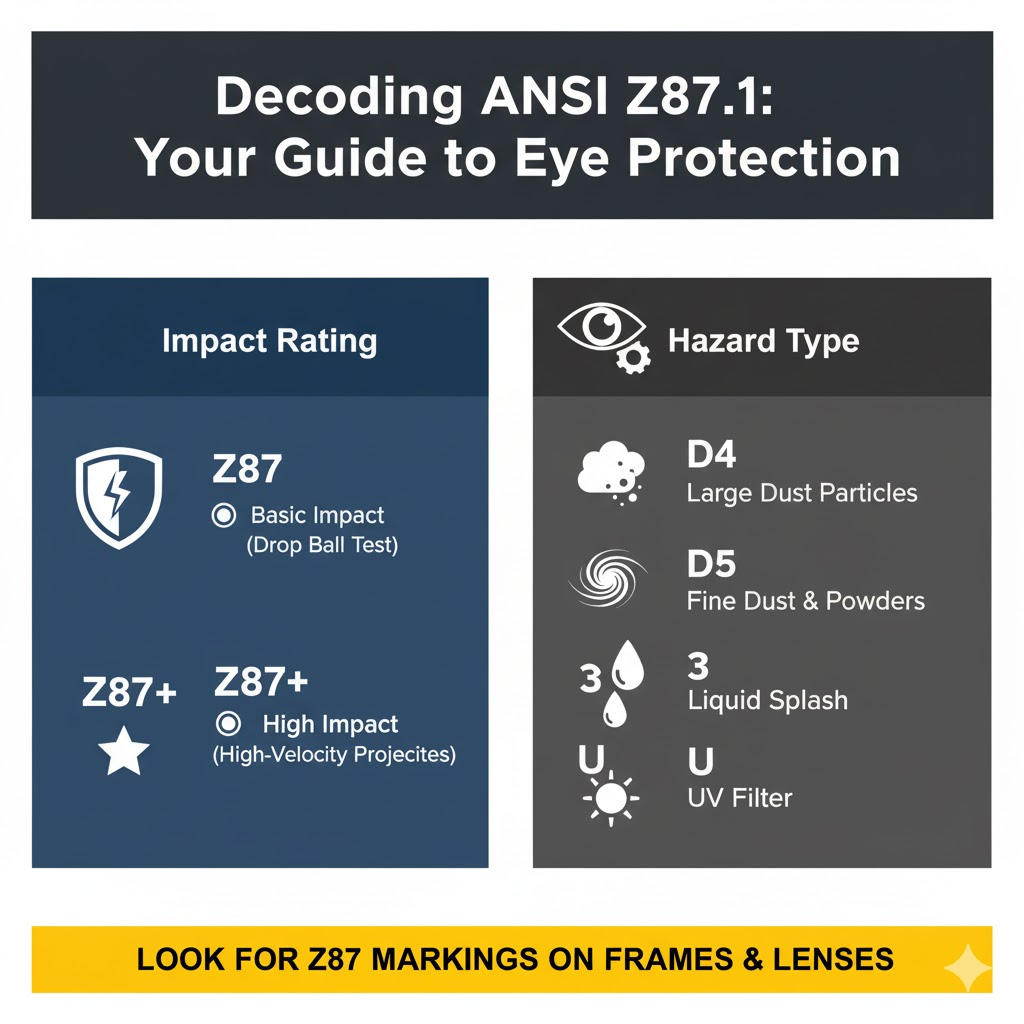

Understanding Safety Standards: The Gold Standard (ANSI Z87.1)

For industrial, professional, or high-risk domestic work in the United States, the ultimate certification to look for is the ANSI Z87.1 standard. This rating, set by the American National Standards Institute, ensures your eyewear has passed rigorous testing for impact and clarity.

Decoding the ANSI Z87.1 Markings

Look for the Z87 marking on the frame and the lens. The symbols that follow tell you the level of protection:

| Marking | Meaning | Hazard Protection |

| Z87 | Basic Impact Rated | Tested against a heavy drop ball (basic impact). |

| Z87+ | High Impact Rated | Must pass high-velocity impact tests (e.g., a steel ball fired at high speed). This is the most common requirement for industrial settings. |

| D4 | Dust Protection | Protects against large dust particles (e.g., woodworking). |

| D5 | Fine Dust Protection | Protects against fine dust and particles (e.g., sanding, grinding). |

| 3 | Liquid Splash | Provides a protective seal against droplets and liquid splashes. |

| U | UV Filter | Indicates the level of UV protection. |

Expert Tip: Always confirm both the frame and the lens have the required ANSI markings. An ANSI-rated lens in a non-ANSI frame is not a certified safety product.

Choosing Your Lens Material: Polycarbonate vs. Trivex

When it comes to safety lenses, two materials dominate the market due to their superior strength and impact resistance. The best choice depends on your specific needs for clarity and durability.

1. Polycarbonate Lenses

- Pros: Most popular choice for safety glasses. Highly impact-resistant (up to 10 times more than standard plastic). Lightweight and naturally blocks 100% of UV rays. Meets the toughest impact standards.

- Cons: Softer surface requires a high-quality scratch-resistant coating for durability. Offers slightly lower optical clarity than Trivex.

- Best For: High-risk construction, machining, heavy-duty industrial work, and any environment where maximum impact protection is the priority.

2. Trivex Lenses

- Pros: Very high impact resistance, similar to polycarbonate. Offers superior optical clarity (less distortion) and is often even lighter than Polycarbonate.

- Cons: Slightly more expensive than Polycarbonate.

- Best For: Precision work where clear, crisp vision is essential, such as detailed laboratory tasks, electrical work, and painting.

The Selection Process: 5 Steps to the Perfect Pair

Choosing the right prescription safety glasses is not about buying off the shelf. It requires a tailored approach based on an assessment of your workplace, your vision needs, and your fit.

Step 1: Conduct a Hazard Assessment

Before you look at styles, identify the exact risks in your environment. This determines the type of protection you need.

- Flying Particles (Woodworking, Grinding): Requires Z87+ High Impact rated lenses and frames, often with wraparound side shields.

- Chemical Splashes (Lab Work, Cleaning): Requires indirectly vented safety goggles (marked with ‘3’) for a sealed fit around the eyes.

- Intense Light/Radiation (Welding, Outdoors): Requires specific filter ratings (EN 169 for welding) and UV/Polarized coatings.

Step 2: Get an Up-to-Date Eye Exam

An accurate, recent prescription is essential for custom safety eyewear. A good fit starts with good vision. Consider your specific vision correction type:

- Single Vision: Best for tasks that require focus at one distance (e.g., a machinist’s work area).

- Progressive or Bifocal Lenses: Ideal for workers who need clear vision at near, middle, and far distances (e.g., a foreman reading blueprints, operating equipment, and overseeing the site).

Step 3: Choose Essential Lens Coatings

Coatings are not optional upgrades—they are essential for performance, durability, and comfort.

- Anti-Scratch Coating: Non-negotiable for all safety lenses, especially softer Polycarbonate, to ensure longevity and clear vision.

- Anti-Fog Coating: Critical for environments with high humidity or frequent temperature changes (indoor/outdoor work, cold storage).

- UV Protection: Must-have for outdoor work to guard against long-term eye damage from harmful rays.

Step 4: Ensure a Proper Fit

A poor fit is a safety hazard. Glasses that slip down or leave gaps defeat the purpose of protective eyewear. Prescription safety glasses should be professionally measured and fitted by an optometrist or certified technician.

- The frame must sit close to the face to minimize gaps.

- The frame should be supported comfortably on the bridge of the nose without pinching.

- The temples (arms) must rest securely over your ears and not move during activity.

Step 5: Select Frame Design and Material

Choose frames made from durable, non-flammable materials like Nylon or high-quality plastic. A wraparound frame design offers superior peripheral coverage, preventing debris from entering the sides. Modern safety frames are comfortable and often feature adjustable nose pads for all-day wear.

Benefits of Investing in Custom Prescription Safety Glasses (E-E-A-T)

Investing in high-quality, certified prescription safety glasses delivers significant returns that go beyond simple compliance.

Enhanced Productivity and Focus

Eliminating the need to wear one pair of glasses over another removes discomfort, visual distortion, and the constant need to adjust slipping eyewear. Clear, undistorted vision directly correlates with higher task accuracy and efficiency, especially in precision work.

Cost-Effectiveness in the Long Run

While the initial cost is higher than non-prescription options, proper safety eyewear is a proven cost-saver. It protects your expensive daily glasses from damage and, more critically, prevents costly medical bills, lost work time, and potential litigation resulting from preventable eye injuries.

Research Note: According to the Centers for Disease Control and Prevention (CDC), wearing the correct protective eyewear can prevent approximately 90% of all workplace eye injuries.

Conclusion: Protect Your Sight, Invest in Clarity

For anyone who requires vision correction, prescription safety glasses are the only way to ensure uncompromised protection and clear vision in any hazardous environment. By focusing on certified standards like ANSI Z87.1, choosing highly durable materials like Polycarbonate or Trivex, and prioritizing a professional, custom fit, you make a confident and responsible investment in your long-term eye health and productivity. Don’t settle for less when it comes to the safety of your sight.

You May Also Like: Wrist Aficionado: The Ultimate Guide for Luxury Watch Enthusiasts